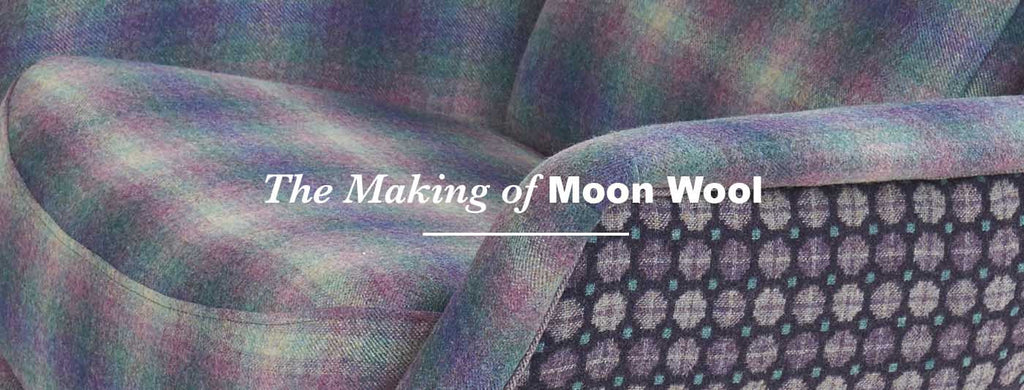

Many of our most exquisite items feature Moon Wool, a sumptuous fabric which is created via a combination of modern industry and traditional techniques. If you’ve been looking longingly at our sofas and armchairs which contain Moon Wool you’ll know all about the beauty of the fabric, but you may not know how it makes the transition from keeping sheep warm to adorning stunning pieces of furniture.

Abraham Moon & Sons have been manufacturing woollen products since 1837, and they remain one of the last vertical mills left in the UK. Based in Guiseley, West Yorkshire, they purchase the majority of their wool from farms in South Africa (for Merino Wool) and New Zealand (for Pure New Wool). Buying from the same suppliers helps them to maintain the highest standards for their finished products.

The raw wool is cleaned and combed upon its arrival, in order to remove impurities which can affect the quality. Wool is dyed in the company’s own Dye House, where they are able to choose from more than 500 shade and colour options. Their specialist dyers work to specific recipes, much like a cordon bleu chef, to create the desired effects. It’s perhaps not surprising to hear that these recipes are a closely guarded secret.

Of course, there’s more to finished wool than just a single colour. The blending stage allows for several shades and colours to be brought together in order to provide eye-catching patterns. Checked designs in particular can feature a glorious combination of hues which give the final effect a somewhat magical quality. Once the blending has taken place, the next part of the process is known as carding.

The process continues…

Blended wool is lubricated with oil and water before carding, during which it is passed through an array of rollers which tease the fibres in different directions. This takes away any remaining impurities and leaves the wool wonderfully soft to the touch. At this stage, uniformity and alignment can be verified and perfected before the wool is wound onto spools.

The spinning, warping and weaving processes turn the wool into the fabric that we recognise in its finished form. A strong thread is created as it’s wound onto cones which can hold a staggering 16000 metres of wool, before the warping and weaving takes place. These enable the yarns to be woven together to create the desired effect. After washing with water from an 800-ft deep borehole, the wool from Abraham Moon & Sons is ready to be delivered to our craftsmen.

The next time you sit on our gorgeous fabric armchairs, spare a thought for the wool that adorns it. This iconic fabric will have gone on a long journey to its destination, but one look at the finished product will tell you that it was all worth it in the end.